TRACK/CAMBER AXLE PRESET

AuE is the technology and world market leader for setting and measuring multi-link front and rear axles for passenger cars and SUVs. Whether electric drive or combustion engine, our systems simulate real conditions for behavior under different load profiles and changing dynamics. The facilities provide the chassis ready for final vehicle assembly. "At the end of the line, AuE systems are used to adjust chassis in the complete vehicle via automated tie rod adjustment.

Our benefit: the greatest possible flexibility

Modern chassis are technical masterpieces. Individually matched to the vehicle type and embedded in the vehicle electronics, they form the basis for safety and perfect driving dynamics.

Increasing complexity calls for equally finely tuned measuring and adjustment technology for toe and camber, including axial runout measurement and ABS testing. The diversity of variants, in turn, demands the greatest possible flexibility.

Depending on the requirements for the degree of automation, AuE Kassel implements suitable systems for axle presetting:

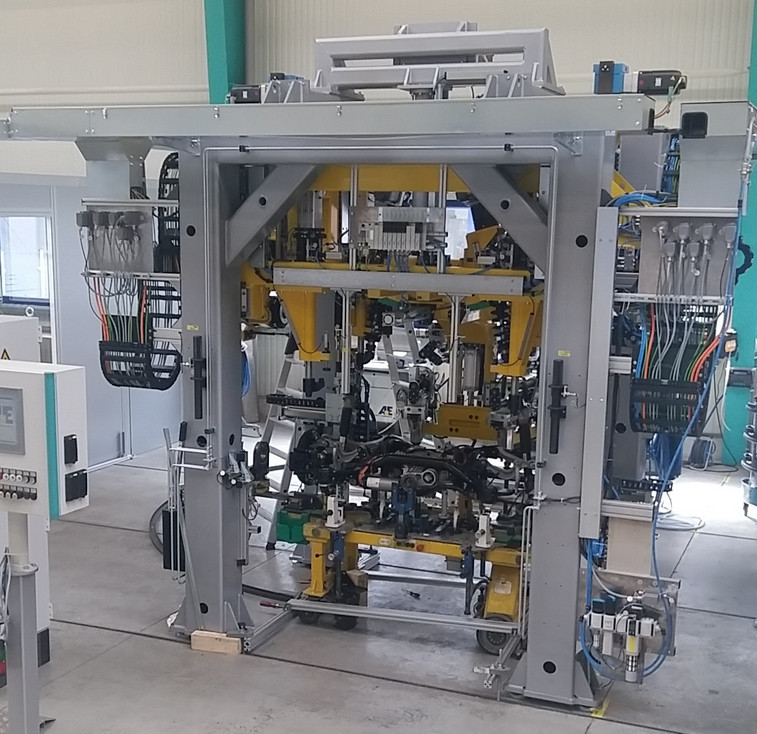

Fully automatic adjustment technology for multi-link axles

AuE setting systems offer the greatest possible variety in the combination of test features. These systems are used for high volumes and can also be used flexibly for changing types. Directly integrated into the production flow, they guarantee the shortest cycle times and the smallest space requirements with an excellent cost-benefit ratio. The track/camber adjustment is carried out under real vehicle conditions, and the adjustment data is recorded and archived.

As an alternative to the bridge machine design, we also realize these machines in bed design with robot loading.

Additional functions and tests can be integrated.

The axle leaves the machine preset and bolted with final torques.

Fully automatic adjustment technology via tie rods

The adjustment of the vehicle axle via the tie rod "offline" during axle assembly or "end-of-line" during final vehicle assembly reduces ergonomically critical overhead activities on the vehicle.

Tools used for adjustment can be of positive or frictional design. The majority of these systems are integrated into the "end-of-line" test stand for adjusting front axles.

Semi-automatic adjustment technology for multi-link axles

Partially automated AuE setting systems for multi-link axles are mainly used for medium quantities in conjunction with moderate labor costs. The degree of automation can be designed depending on customer requirements.

Usually, loading is carried out by the worker using load handling devices; depending on the customer's requirements, manual setting and manual bolting can be combined with automatic processes.

The customer determines the degree of automation.

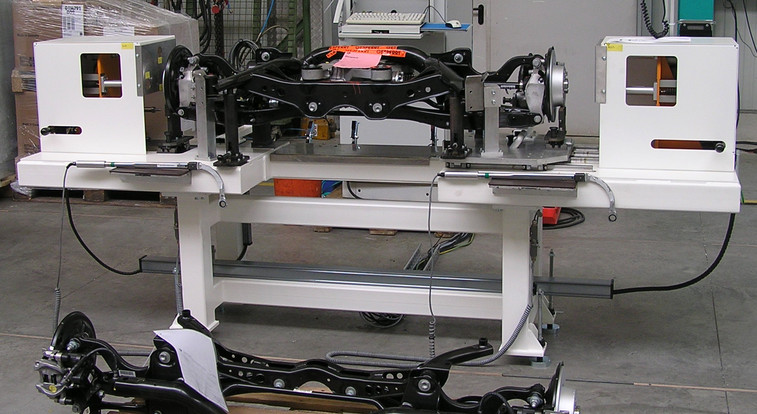

Manual adjustment technology for multi-link axles

This technology is mainly used when no full-scale series or volume process is to be mapped. The systems provide sustainable support for optimization processes thanks to their low investment costs. The tables are used in series production as a back-up to fully or semi-automatic machines or, in the case of very small series, as a quality gateway for the assembly process.