ASSEMBLY LINES FOR AXLES, AXLE COMPONENTS AND E-DRIVES AS WELL AS BATTERY PACKS

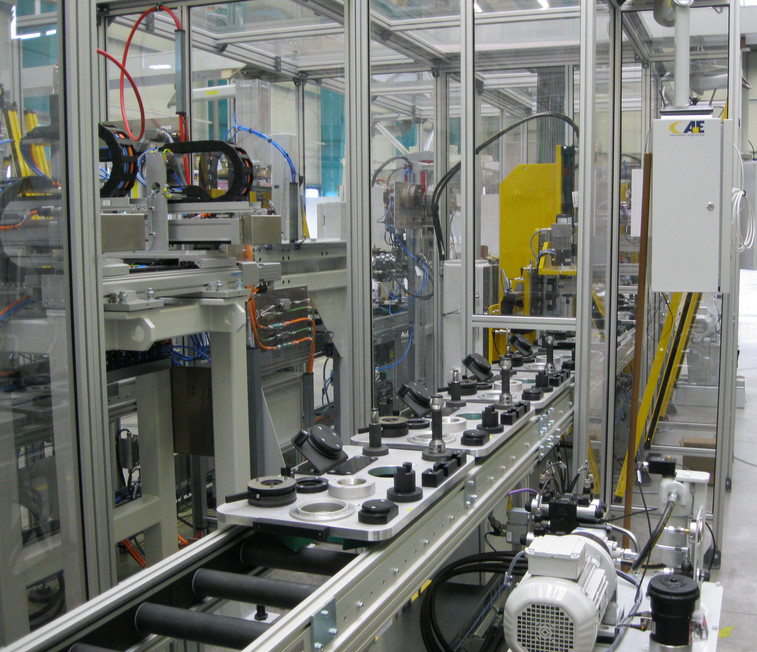

AuE is a sought-after partner for the design and implementation of assembly systems. Our assembly systems for front axles, rear axles, e-drives, battery packs, track rod pre-assemblies, suspension struts, wheel carrier modules, center modules or transmissions are in use worldwide. The spectrum ranges from manual workstations to fully automated systems.

Our benefit: comprehensive process knowledge

Many factors have presented assembly technology with new challenges in recent years. Due to the high complexity of components in vehicle construction and an enormous number of variants with varying volumes, productivity has top priority.

In addition, integration into JIT and JIS processes as well as increased requirements for safety and documentation demand comprehensive process knowledge on the part of engineering.

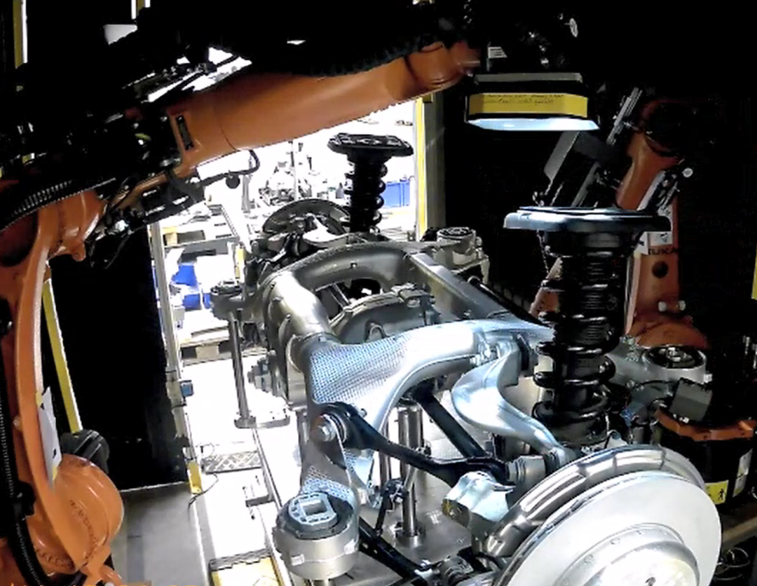

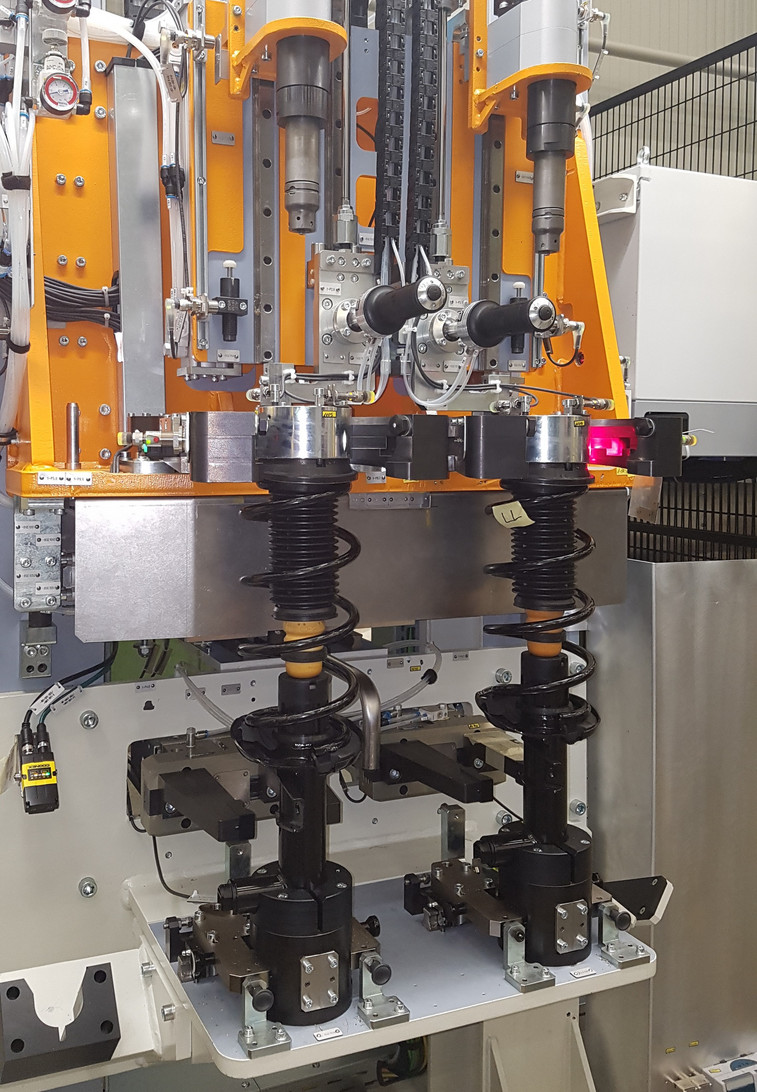

Assembly technology for axles and axle components demands top performance in terms of process know-how, precision and process reliability.

This is mainly due to the fact that the behavior of an axle in the partially assembled state deviates significantly from the CAD model.

Nevertheless, in the final assembled state, the axle must have exactly the same geometry as specified by the chassis designer. The integration of test and inspection equipment into the assembly line is therefore of outstanding importance in line planning.

Assembly systems for e-drives show many parallels to axle assembly, whether due to many man-machine interfaces, requirement for reproducibility or simply due to the comparable weight class.

AuE designs, develops and implements assembly systems for cars, trucks, trailers, motorcycles as well as agricultural and commercial machinery:

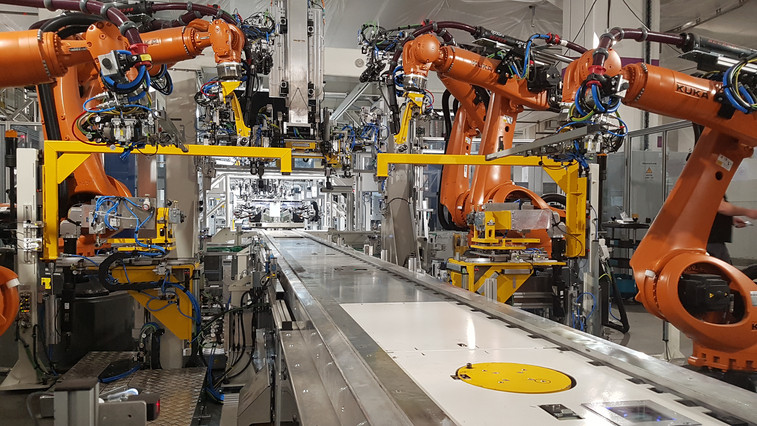

Assembly lines for axles and wheel heads

Axle assembly is the specialty of AuE Kassel GmbH. Whether bolting and joining applications or integrated on- or off-line processes, we solve the tasks around the axle and wheel head assembly holistically, regardless of the mix of manual workstations and automated circumferences.

AuE realizes complete plants, but also supplies individual machines for integration.

The line ranges from low- to high-volume applications, from single-type to high-flex systems.

Depending on the application, we select suitable layouts using standard conveyor technology or AGVs, integrate logistics requirements through pick-at-place or supermarket concepts.

Our customers benefit from our worldwide and cross-customer experience.

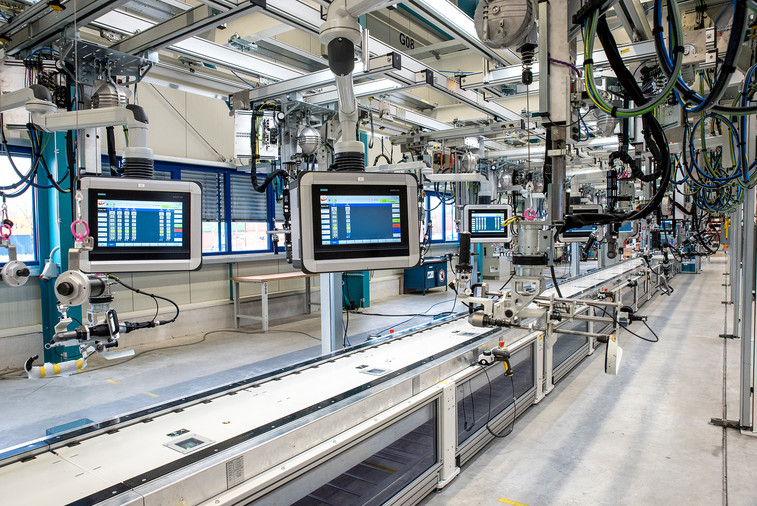

Assembly lines for e-drives & battery packs

Due to our decades of competence in assembly - mainly in the product class up to 300 kg - we are able to realize suitable assembly concepts including variant management, quality assurance, etc. for rotor, stator as well as final assembly of e-drives or for the assembly of battery packs. Here we act together with our parent company Strama-MPS.

Screwdriving machines

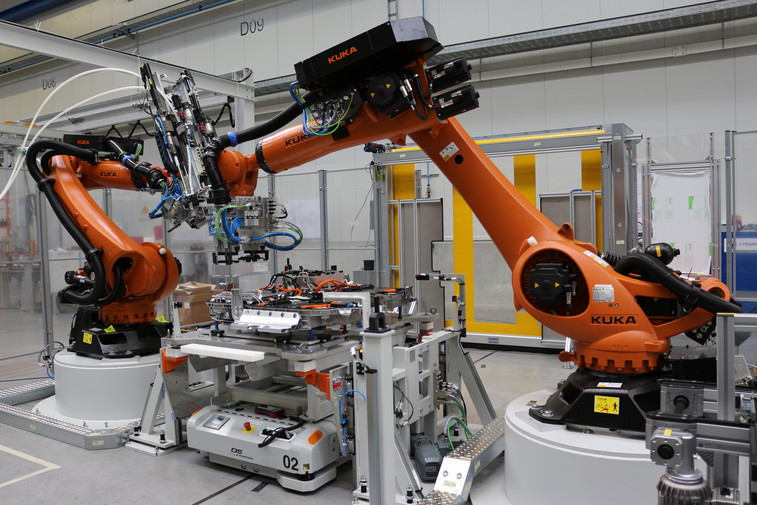

In addition to manual screwdriving processes, in-line screwdriving machines allow a large number of screwdriving operations to be performed in parallel in cycle time (e.g. 60 sec.). Screwdriving machines with up to 18 spindles in portal design as well as robotic screwdriving machines with 4-6 robots have been realized. These machines combine a high number of individual operations on a minimum surface area with high change flexibility.

Handling systems for screwing and assembly

Screwing is a central technique for assembly as well as setting technology. AuE's know-how lies in the design of the tools as well as the connection of the spindles. In addition to screwdriving machines (see above), AuE uses its own standard catalog for handling systems and screwdriving applications. From this, we develop customer-specific solutions for a wide range of different screwdriving applications. Handling systems for joining processes are also based on this catalog.

Quality gate

Quality inspection in the assembly process or as a final inspection has become established as a standard in the industry for safety-relevant assembly scopes. AuE realizes this requirement by own design or by integration and thus supports the customers in their zero-defect requirement.

Assembly lines for gearboxes

Whether axle drives for passenger cars or motorcycles, whether transmissions for agricultural machinery or rework line complementary to the series plant. AuE conceives and realizes machines and plants and contributes its know-how in measuring (e.g. friction values), assembling (e.g. iterative bolting), testing. The interlinking of the assembly process, the integration of manual workstations, for all this AuE takes over the responsibility.

Assembly lines for suspension struts

As stand-alone stations or directly integrated into axle lines, suspension strut assemblies are characterized by a high diversity of variants. Safe machines, in cycle time with coherent integration of all quality-relevant specifications, this is what distinguishes our machines.