PINPOINTED FLOW OF MATERIALS

Save space, save time, save costs, but keep availability high.

AuE acts according to this maxim in all solutions for material flow and production logistics.

Our benefit: decades of experience

The origins of AuE Kassel GmbH go back to the development and manufacture of complex systems for handling, material flow and interlinking. More than 1000 delivered systems are the countable proof of our close partnership with international key industries.

Even with JIT concepts, storage locations and decoupling modules are absolutely necessary to compensate for different cycle times or production engineering processes and possible process delays in manufacturing and assembly.

AuE develops customized solutions for automated handling, optimally designs standard conveyor technology to meet your conditions, automates parts handling, and ensures that the material is provided exactly at the right place, at the right time, and with the lowest possible number of interfaces.

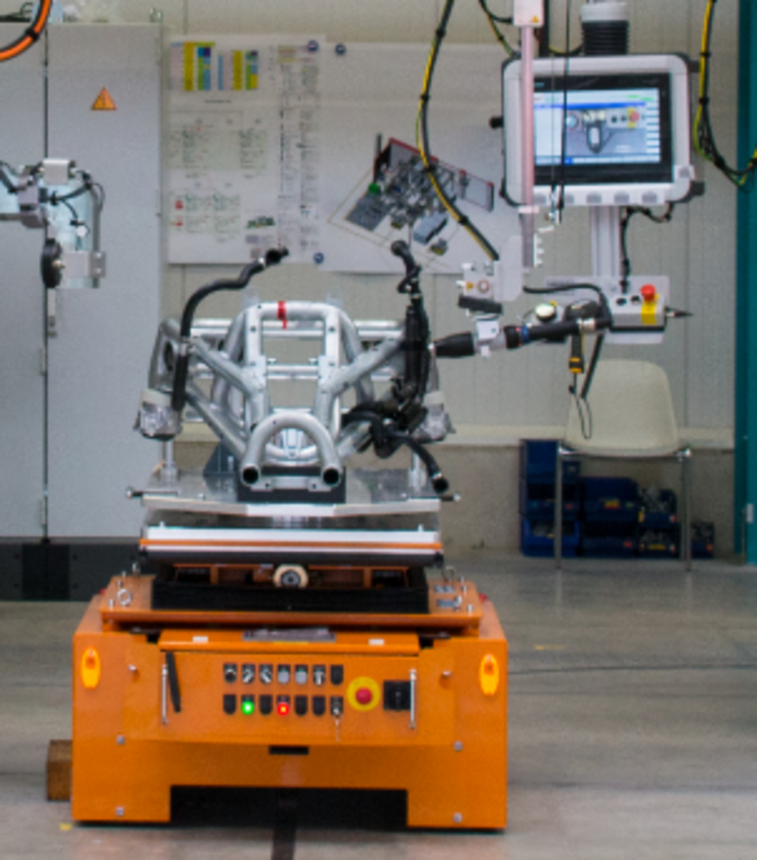

Flexible assembly with DTS / AGV

MonFlex® is a highly flexible concept of a driverless transport system. It represents a mobile assembly platform, which allows to work directly on the FTF, to introduce forces and moments. With it, picking and assembly areas can be flexibly set up and interlinked according to requirements.

With this modular concept, we adapt to customer requirements with regard to track guidance, stop-and-go or flow production, loading procedures, external communication, safety technology and other technical equipment, among other things.

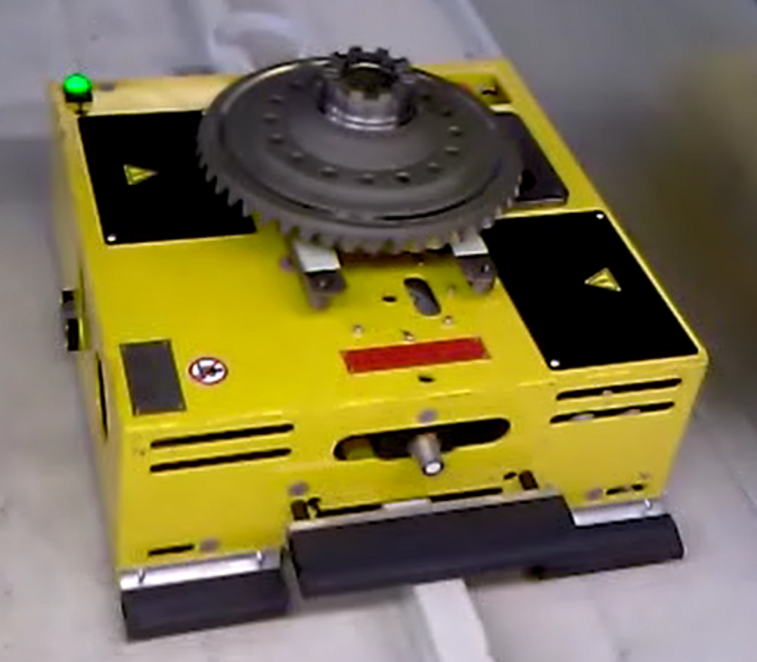

Shuttle pallets

Shuttle are characterized by high energy efficiency, long conveying distances and individual routing. They can be used both for automatic parts transport and as transport vehicles for assembly tasks.

Decoupling modules

Decoupling modules are used for intermediate workpiece storage and have the task of decoupling work processes from each other or coupling areas with different manufacturing processes. They often separate areas with make-to-stock production from areas with sequential assembly. They are also used as a central logistics element in component production.